Ship and Barge

Fabrication

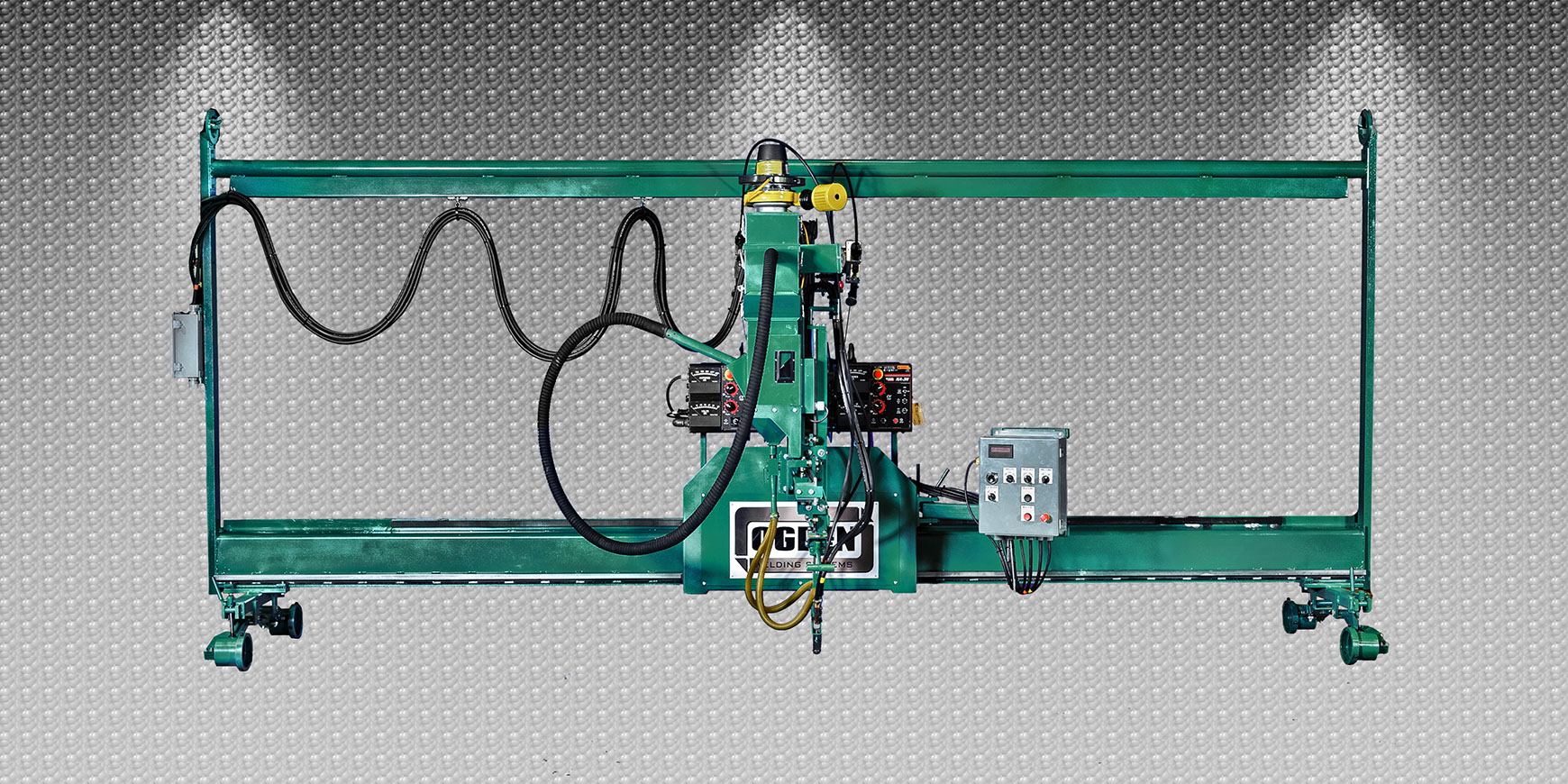

Service Gantry

• Eliminates manual time consuming positioning of weld controls and cables

• Independent, powered, lifting mechanisms easily position weld controls and mig gun.

• Multiple operators can work independently in various areas of the stiffened plate to complete welds between web frames and the pre-stiffened panel

• Gantry mounted ground shoes provide weld grounds through rails to work piece.

• Optional smoke extraction removes hazardous welding fumes away from operators to a centralized smoke removal system.

The Service Gantry spans the panel line and travels on floor and/or wall mounted rails. It serves as a moving work station that supports components used to manually finish weld pre-located webs, stringers, frames, brackets or miscellaneous parts on a

panel.

Multiple manually operated work stations are suspended from the upper gantry frame. Each weld station contains a MIG welding unit, an oxy/fuel cutting torch assembly, a compressed air line for use with pneumatic hand tools, and provisions for shielding gases. Each work station is mounted to the upper gantry frame via a motorized trolley and hoist. Each hoist can be moved along the upper beams and lowered into position at each welding location by a wireless transmitter.