Ship and Barge

Fabrication

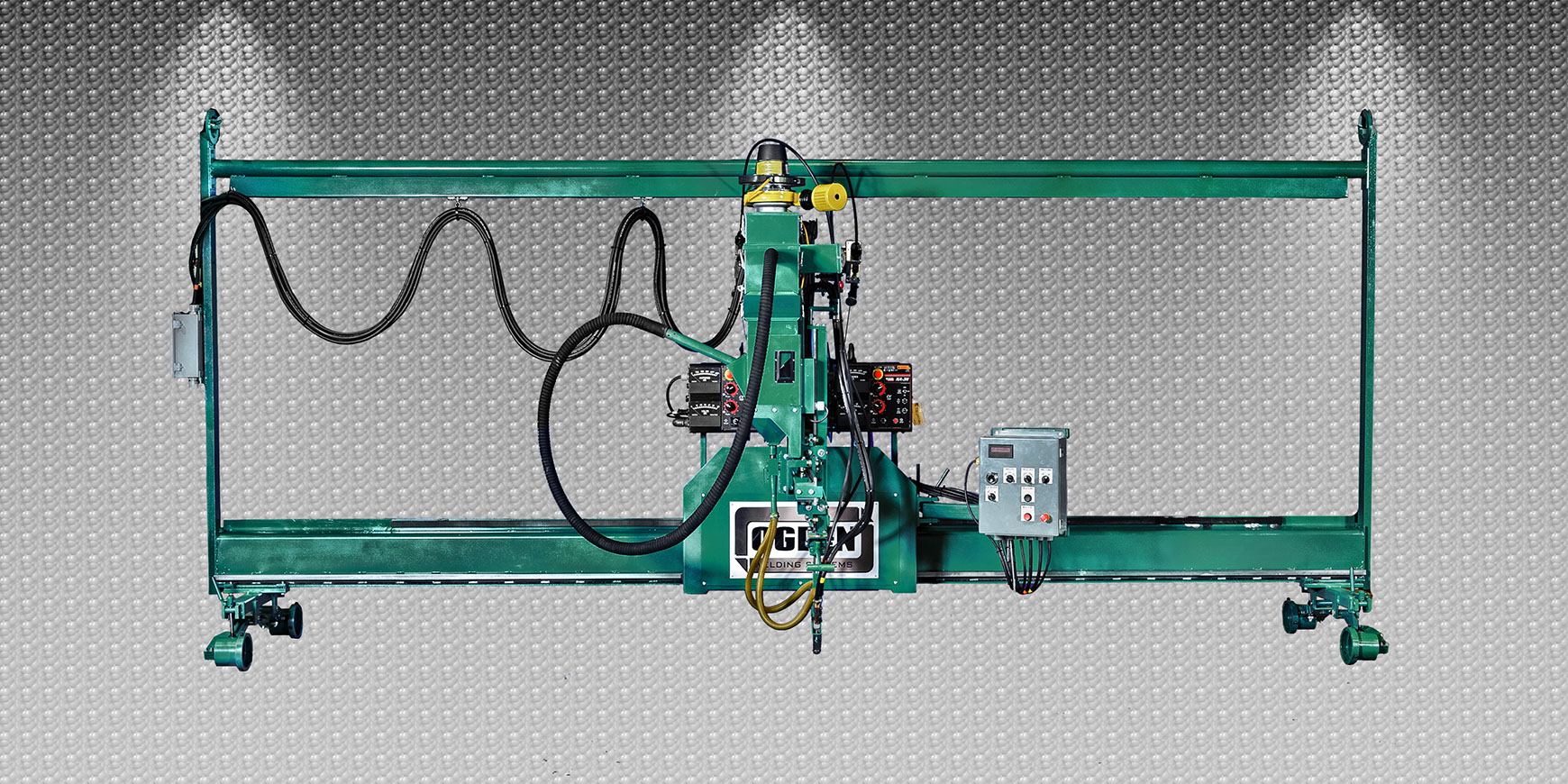

One-Sided Welder

• A heated flux system provides automatic dispensing, removal, and recycling of the flux.

• Adjustable guide rollers combined with automatic seam guidance maintain lateral torch alignment. Laser guidance is also available.

• Multiple sub arc torches deliver high quality, uniform welds from the top side of the plates.

• Eliminates turning over large plates to achieve higher productivity and lower costs.

• A single operator can completely seam weld a panel in less than 60 minutes.

• When equipped the ESAB ICE process:

- ICE one side welding has nearly half the heat input of three wire welding with higher deposition rates

- ICE seam welding provides a high deposition rate with very low heat input and produces an x-ray quality weld

- One DC and one ICE AC welding torch are mounted to a motorized carriage with a rack and pinion drive

- The ICE welder works in conjunction with a magnet hold down system that assures accurate plate orientation without tacking by using magnetic clamping without magnetic interference

- The ICE system produces consistently flat panels

The One Side Welding System consists of three integrated systems to load, fit and weld multi-plate panels. The systems are:

The Material Handling System is designed to load, transport and position steel plates through the different work stations. This system gives a structurally sound work table throughout the entire length. Each station is supplied with the plate support and positioning components which are required for the task each station provides.

The Magnet Bed System is a heavy duty electro-magnet fixture designed to fit and hold steel plates in position for seam welding. The fixture uses a grooved copper flux back-up bar that supports the bottom of the weld joint. Each magnet bed section has two parallel rows of magnets, one row on each side of the flux back-up bar. Each section is individually controlled. Side rollers are provided to protect the magnets from damage when moving incoming plates or reversing outgoing plates. Manual plate stops assist in the alignment and centering of plates over the magnet bed.

The One Sided Seam Welder welds plates to form multi-plate panels, without the need to flip the panels over to weld a back bead. A bridge beam supports a movable carriage that carries the welding equipment and controls. The welding controllers and the operator interface (touch screen) controls are grouped together on the carriage. The carriage uses a rack and pinion drive mechanism controlled by a solid state variable speed controller to provide the precise travel required for seam welding.